Description

Specifications

| Rim | |

| Wheel Size | 700c |

| Tire Compatibility | Clincher/ Tubeless |

| Bead Type | Hooked |

| Rim Depth | 40mm |

| Inner Width | 21mm |

| Outer Width | 28mm |

| Hub | |

| Front Hub Spacing | 12x100mm / QR x 100mm |

| Rear Hub Spacing | 12x142mm / QR x 135mm |

| Bearing | S&S Ceramic |

| Brake Compatibility | Disc (Center Lock) |

| Freehub Type | 4 Pawls |

| Freehub Compatibility | Shimano / SRAM XDR / Campagnolo |

| Spoke | |

| Front Spoke Pattern | 2X/Radial (2:1) |

| Rear Spoke Pattern | 2X/1X (2:1) |

| Spoke Count | 21F/24R |

| Spoke Type | Carbon Spoke (3.2mm) |

| Nipple Type | Alloy Secure Lock |

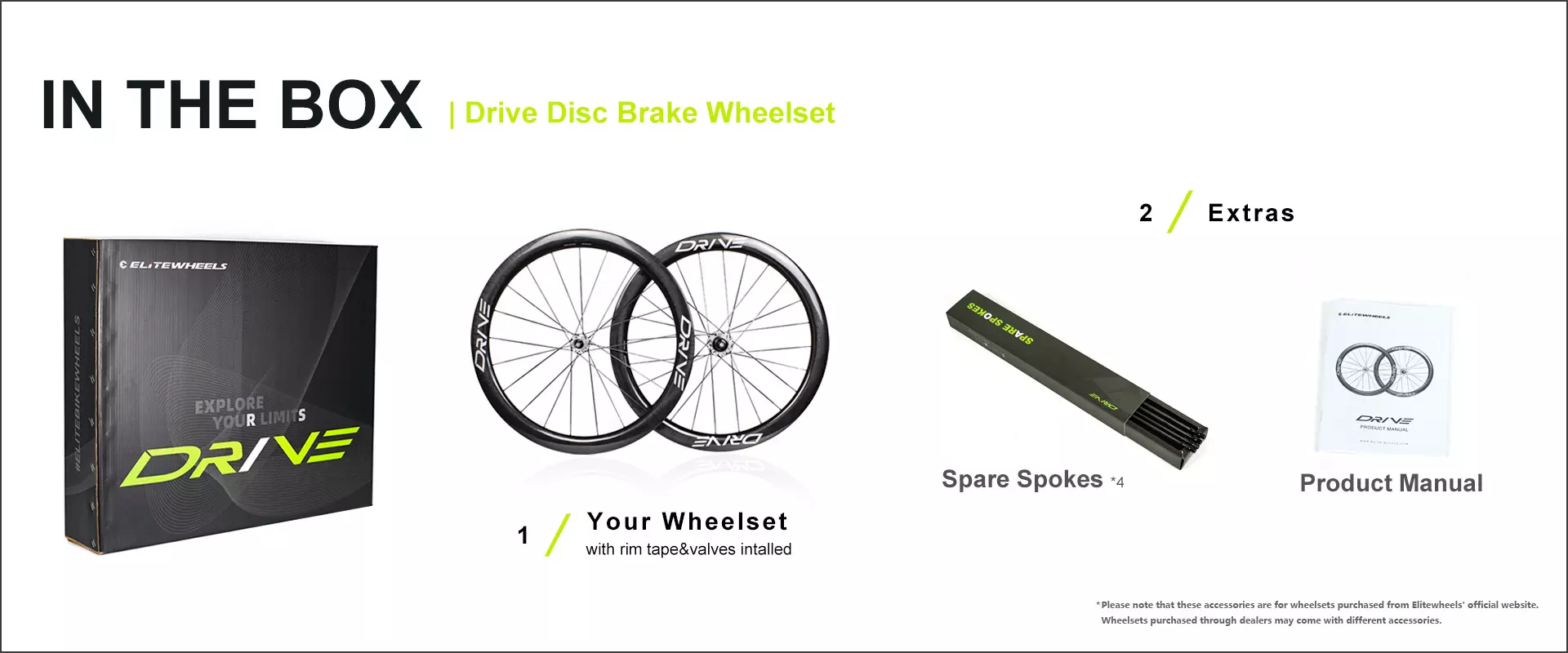

| Spare Spokes | 4PCS |

| Other | |

| Rim Finish | Glossy Marbling Black |

| Extras | Pre-installed Rim Tape & Tubeless Valves |

| Weight (Pair) | 1260±30g |

| Rider Weight Limit | 275lbs/125kg |

| Recommended Tire Sizes | 700 x 25-38C |

| Certification | UCI Approved, CE Certified |

DRIVE RIMS

At Elitewheels, we design our Drive wheels to match the needs of professional riders. In order to deliver the best performance, we incorporate our own UNI carbon fiber, a specific ratio of T800 and T1000 carbon fiber (*Read more about UNI technology), making rims not only strong, but also exceptionally light and stiff. The U/V-shaped rim profile of the Drive 40D was chosen to make the rim both aero as well as stable in windy conditions. The Drive 40D’s 21mm inner rim allows for wider tires to be run, allowing for more comfort and grip.

CARBON SPOKES

What separates the Drive 40D from most other wheels is its use of high-modulus carbon spokes. They are 3.2mm wide aero bladed spokes, offering 7% more lateral stiffness as compared to equivalent steel spokes. The carbon spokes are mechanically secured, giving the benefit of being able to be trued and maintained just like regular steel spokes. Anti-loosening technology is also incorporated into the spoke nipples. The threads built into the nipples give them a double-locking effect.

PERFORMANCE HUB

To get the most out of carbon fiber spokes, we specifically designed the hub with high flanges to further increase lateral stiffness and improve handling. Elitewheels manufactures its own high precision hubs with Fanuc CNC machines, which can machine to tolerances of just 0.02mm. This not only allows for lower rolling resistance but also increases bearing longevity.

CERAMIC BEARINGS

The 40D’s front hub uses two 6803 mixed ceramic bearings. The rear hub uses one 6903 and three 6803 mixed ceramic bearings. These large bearings offer better rigidity. The use of mixed ceramic bearings will allow you to have a more efficient bike, saving you precious watts.

In order to provide riders with the best wheelsets, we seek to update and improve them as technology advances. Elitewheels reserves the right to change, add or remove the information contained on this website at any time, including equipment, specifications, models, colors, materials, and pricing, without prior notice. The shipped products will be based on the actual order information. Elitewheels thanks you for your understanding and support.

Frédéric (verified owner) –

Génial ! C’est ma deuxième paire de roue. Après les Drive50 disques je suis passé au 40. Toujours aussi fabuleuse. Rigide en latéral et confortable en vertical. Elles glissent sur la route sans bruit. Le vélo est sublimé par ses roues. Beaucoup plus adapté pour les ascensions, leur faible inertie rend l’effort plus lissé et le vélo plus réactif en relance. Vraiment bluffant ! Qualité de fabrication remarquable, pas de jeu, de voile, pas de bruit. Pesé à 1270g. J’ai fait 15000km avec mes 50 sans aucun souci (comme neuve, pas de voile ou de jeu).

EDUIN CERVANTES –

COMO PUEDO COMPRAR SOLO LA RUEDA DELANTERA PORQUE LA DAÑE

SOLO ME APARECE EL JUEGO

Patrick –

Hola Eduin. Por favor contacte con nuestro servicio de atención al cliente. Ellos podrán ayudarle a conseguir la nueva rueda.

Guichard –

Très belles roues. Finition haut de gamme. 1330G avec rim tape en 45mm. Pratiquement équilibrées en rotation avec chambre a air et pneu. Grande fluidité des roulements. Roue libre agréablement sonore mais sans excès. Grand confort de roulage. Première crevaison : pneu remonté sans outil (GP5000TT). Aucun voile constaté après 500km.

Patrick –

Bonjour. Merci d’avoir pris le temps d’examiner la paire de roues. C’est formidable d’entendre que vous êtes satisfait des roulements, de la roue libre, du poids et de l’installation des pneus. Nous apprécions vos commentaires.

Joakim (verified owner) –

Really love the wheels, light, durable, fast and goodlooking as well.

I´ve used them for a year now and they are still perfecly true, no maintenance has been performed.

Also the sound from the rear hub is amazing.

Patrick –

Hi Joakim. It is nice that you are liking the performance and appearane of the Drive 40D wheelset. We are happy that they have been maintenance-free and that you are satisfied with the hub sound.

CESAREO SANZ TRIS (verified owner) –

Segundo juego de ruedas ( DRIVE 40D) en este caso con bujes cromados, ya montadas las dos bicis con las rueedas

Patrick –

Hola Cesáreo,

Es bueno ver que su experiencia con las ruedas 40D ha sido lo suficientemente positiva como para adquirir un segundo par. Además, gracias por las estupendas fotografías.

Ivan giuseppe (verified owner) –

Ciao dopo le 50d ho acquistato anche le 40d che uso per le giornate ventose che qua in Trentino c’è abbastanza di frequente e per l’estate quando farò tanto dislivello.

Passando alla valutazione delle ruote posso dire che sono molto leggere e scattanti rigide il giusto io le ho montate con camere in tpu ricevute in regalo e sono molto scorrevoli e non troppo dure quindi dopo 300 km fatti posso dire che sono ruote costruite molto bene probabilmente anche migliori di tante ruote di marchi famosi ad un prezzo ragionevole.Ricevute dopo 2 settimane circa e sempre informato dove si trovava il pacco e ho ricevuto un sms il giorno della consegna tutto molto semplice preciso.

Grazie sono molto soddisfatto Naturalmente le consiglio a tutti quelli che vogliono pedalare con ruote Top

Ivan

Patrick –

Ciao Ivan,

Grazie per aver dedicato del tempo per scrivere questa recensione. È bello che ti piacciano entrambe le ruote. Siamo felici di sapere che li trovi leggeri per le salite e abbastanza rigidi. I tubi in TPU rendono l’arrampicata ancora più piacevole. È bello vedere che sei soddisfacente e al livello delle migliori ruote disponibili.

CESAREO SANZ TRIS (verified owner) –

Impresionantes ruedas, muy ligeras, rigidas, muy bonitas, calidad premium, calidad precio inigualable.

Patrick –

Hola César. Gracias por las bonitas fotos. Las ruedas quedan muy bien en tu Trek y Orbea. Nos alegra que estés disfrutando de los 40D.

Stan (verified owner) –

Great looking wheels. Very light weight. The sound of the rear hub is amazing, loud but awesome. The wheels ride nice and free, definitely can tell the difference on a high speed downhill section. Shipping took about 2 weeks, so not as long as I thought.

Patrick –

Hi Stan. Thank you for sharing your experience of the 40D so far. The wheelset looks nice on your Canyon.

Bill Sykes (verified owner) –

I purchased the Elite Drive 40 wheels for a new Trek Emonda SLR9 which I have built up. The quality seems excellent and, although, due to winter weather, have only ridden them three times. They look fantastic, very nicely finished. I got the black decals which are more subdued. I checked them on my truing stand and they were bang on. Installation of the tires (Pirelli P-Zero 28c) was easy. Normally I would substitute the rim tape and valve stems for Muc-off but the tape and valves that came with the wheels seemed fine. I used SRAM rotors and they installed normally.

I would recommend these for sure.

Niels W (verified owner) –

I was looking for light climbing wheels and ended up at Elitewheels. After much hesitation, finally placed an order. These were delivered in Belgium after 3 weeks (no import duties had to be paid). Not only look good, but give a completely different feel to the bike. The bike has a much more aggressive feel and lightning fast response. Don’t hesitate to buy this one! Highest quality for a low price!

alain (verified owner) –

La livraison a été rapide et l’emballage propre. Je les essaie depuis 15 jours environ.

Les drive 40 D à disques ont une réactivité incroyable. Elles ont rendu mon vélo nerveux. Sur le plat, elles sont très efficace. Sur un parcours vallonné, elles sont d’une incroyable facilité. Très facile à emmener, le confort est également au rendez-vous. La roue avant a cogné dans un trou sans dégât. Elles sont solides

Ces roues tout carbone ont propulsé mon vélo dans un autre monde.

A conseiller sans hésitation.