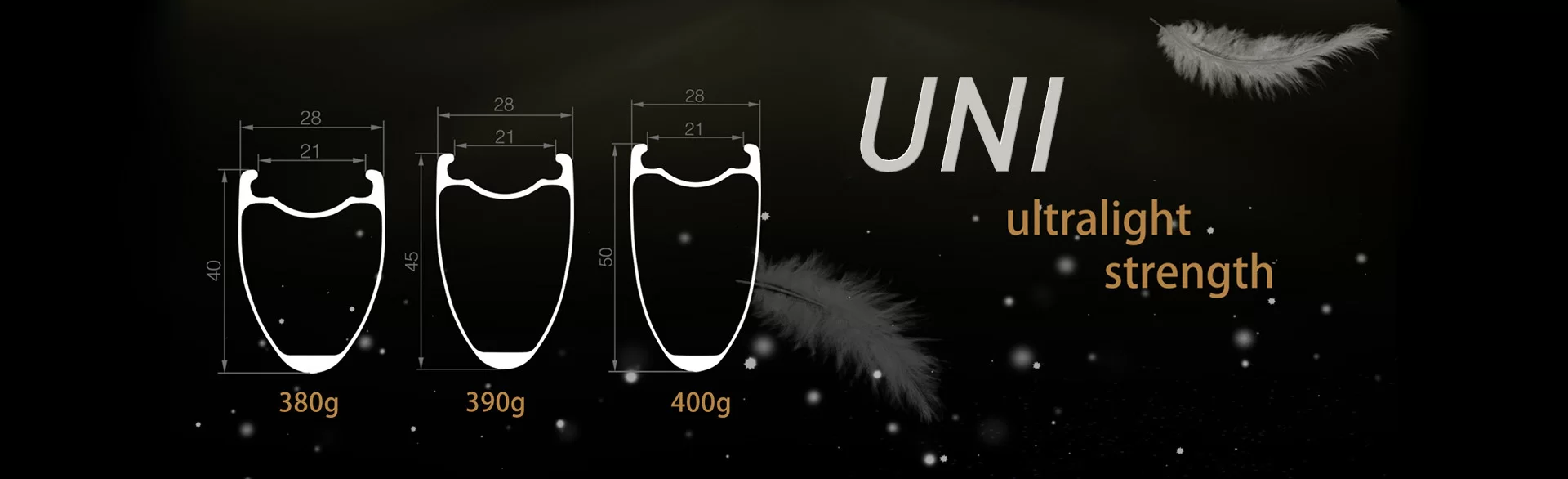

UNI – The Foundation of Our Ultralight Wheelsets

Development

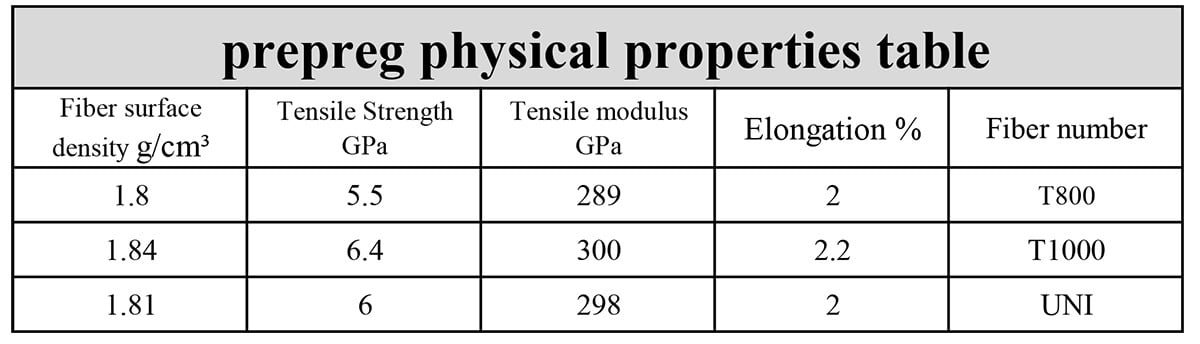

After two years of continuous experimentation with lighter carbon fiber materials and increased research and development of resins by the Elitewheels team, a set of optimal material ratios was finally reached. Our in-house designed UNI carbon fiber has properties that fall between Toray T800 and T1000 carbon fiber. The following table compares the properties of T800, T1000, and UNI, whose tensile strength and tensile modulus are more balanced.

Testing of wheels using UNI carbon fiber has shown that they have a higher strength to weight ratio as compared to wheels made from standard T700 and T800 carbon fiber.

*All test data are from Elitewheels’ test lab

1. Lateral Stiffness

Lateral stiffness in a rim means the amount it moves from side to side given a certain amount of force. Laterally stiff rims feel more responsive during powerful accelerations like sprinting. The stiffer the rim, the more power is transferred to forward motion when riding. Cornering and bike handling in general are also improved.

Under the max load of 50kgf, the Drive 50D rim using UNI carbon fiber deformed by only 9.07mm. This is a lateral stiffness increase of 22% as compared to a Drive 50D rim using standard T700 and T800, which deformed by11.65mm.

2. Vertical Stiffness

Vertical stiffness indicates the amount a rim deforms horizontally given an amount of force. Variables such as tire pressure and rider weight contribute to a slight deformation of the rim which directly affects the rolling resistance of both the rim and tire. The maximum system weight limit of the Drive 50D rim is 130kg. As long as the rider weight limit is not exceeded, rims featuring UNI will roll well on a road surface.

Under a load of 300kgf, the Drive 50D using UNI deforms by 8.2mm, an improvement of 10% in vertical stiffness compared to the same rim (9.06mm deformation) using standard T700 and T800 carbon fiber.

3. Spoke hole tension

The ideal spoke tension value ensures sufficient rigidity without excessive vibration. Our Drive wheels are designed to withstand 340kgf at the spoke hole. Since UNI carbon fiber has a higher strength to weight ratio, less material is needed for reinforcement. We created two test samples. The UNI Drive 50D rim had 3mm of reinforcement, while the 50D rim using standard T700 and T800 carbon fiber had 3.2mm of reinforcement.

In the test, both rims failed at roughly the same spoke tension. This reduced need for reinforcement allows the our wheels with UNI carbon fiber to be made lighter without sacrificing strength.

*Spoke holes are drilled at specific angles to reduce stress placed on carbon spokes, significantly decreasing the likelihood of failure. The spoke holes are drilled at angles between 3.4°-8.2° depending on their location and on the length of each hub’s flange.

4. Impact Resistance

At Elitewheels, we make sure that all of our wheels can pass not only the UCI Vertical Impact Test, but also our own impact test standard, which involves twice the energy, 80 joules. This testing is important to ensure the safety of a wheel during a collision. All of our Drive road and gravel wheelsets have been UCI certified, allowing them to be raced even at the highest level of pro competition.

*All of our wheels have passed more than 20 other tests, including a variety of others related to durability, stiffness, longevity, torque fatigue, tire pressure, etc. Wheels are also tested by our six sponsored UCI Continental teams.

Wheels featuring UNI

Elitewheels makes multiple wheels that feature UNI carbon fiber. All of the wheels in our Drive road, Drive Helix, and Drive Gravel G45 series with replaceable carbon and steel spokes feature UNI carbon fiber. Rims made using UNI feature wider, more modern inner widths, allowing them to fit wider tires. They are the ultimate performance wheelsets and are raced by our six sponsored UCI Continental pro teams.