What are Bearings?

Bearings are mechanical components designed to reduce friction between moving parts and to support and guide rotational or linear motion. On a bicycle, bearings are used in wheel hubs, bottom brackets, headsets, jockey wheels, and suspension forks.

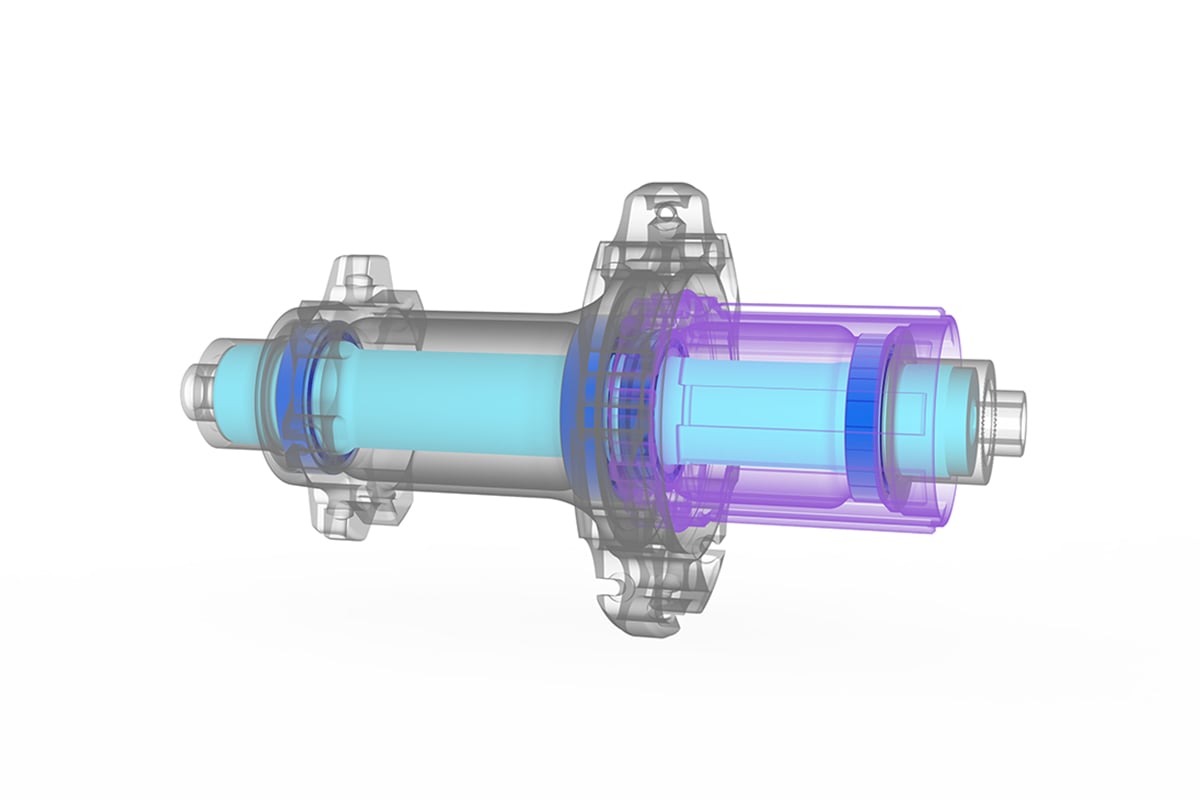

Sealed Cartridge Bearings

In our wheels, we use sealed cartridge bearings. This type of bearing consists of bearing components are enclosed within a sealed, self-contained unit.It features four main components. The advantages of sealed cartridge bearings is that they are sealed to prevent ingress of contaminants, reducing wear and increasing durability. Being self-contained, they are easier to replace and install.

Parts of a Bearing

Inner and Outer Races

These are the rings that house the rolling elements and provide the surfaces on which they roll.

Rolling Elements

Rolling elements are the balls or rollers that roll between the inner and outer races to reduce friction.

Cage

A cage keeps the rolling elements evenly spaced and prevents them from contacting each other.

Seals

Seals are protective barriers that enclose the bearing, keeping contaminants out and lubrication in.

About Ceramic Bearings

Ceramic bearings use ceramic balls made of silicon nitride (Si2N4) rather than traditional steel or metal alloy.

The Benefits of Ceramic Bearings

Ceramic bearings have a number of benefits over steel bearings.

Weight

Ceramic balls can be significantly lighter than steel ones, up to 50% lighter. This contributes to lighter sealed cartridge bearings. While ceramic balls make for a relatively small weight saving, its can add up since each wheelset requires six cartridge ball bearings. Using ceramic bearings is one of the reasons why our wheels can be made lighter than the competition.

Rolling Resistance

Ceramic bearings can be made more spherical and offer lower rolling resistance as compared to steel bearings all things being equal. As a result, they can carry heavier rider loads without stressing the balls or races, while using less lubrication. This means you can roll faster.

Thermal Expansion

Ceramic ball bearings do not suffer thermal expansion like steel bearings.

Corrosion Resistance

Unlike steel ball bearings, ceramic ones do not rust, allowing them to roll smoothly.

Reduced Wear

They are lighter in weight, more resistant to wear, have lower friction leading to less rolling resistance, more corrosion resistant, and experience less thermal expansion. They are also 30% harder than steel bearings.

Full Ceramic vs. Hybrid Ceramic Bearings

Full Ceramic Bearings

There are two different types of ceramic bearings. A full ceramic bearing has ceramic ball bearings, inner and outer rings/races, and cages. While full ceramic bearings have the lowest rolling resistance, they are more meant for applications in the aerospace, medical equipment, and chemical processing industries. Full ceramic bearings, while the lightest option, are less durable because they are brittle, making them unsuitable for hubs.

Hybrid Ceramic Bearings

The type of bearing that is more commonly found in bicycle hubs is the hybrid ceramic. The rings/races and cage are made of steel, while the balls are ceramic. Hybrid ceramic bearings are used in electric motors, machine tools, and cycling. They offer most of the benefits of ceramic bearings, while also being durable enough to last a long time, even longer than steel bearings in many cases.

Not All Ceramic Bearings are Created Equal

In theory, ceramic bearings should offer lower rolling resistance and an increased lifespan. However, that is not always the case. Bearing brands and different standards can make a big difference. In some cases, ceramic bearings are worse than steel bearing. This is because some brands don’t use high-quality ceramic balls or meet the ISO 9001 manufacturing standards. They may require heavier grease and have poor performance.

What Bearings Does Elitewheels Use?

Elitewheels only chooses high-quality ceramic bearings for its hubs, for example S&S and TPI bearings. Information on each wheelset’s bearings can be found on their individual product pages. Most of our wheelsets use premium, S&S hybrid ceramic bearings. These wheelsets include our Drive road, Drive gravel, Velo Six, Marvel, and Velo TT Disc wheels. Our Drive Helix wheelsets feature even more premium TPI bearings, which have tighter tolerances and use harder materials, making them last longer.

Not All Hubs Are Created Equal

Many of the issues riders have with bearings has nothing to do with the bearings. Instead it has to do with machining accuracy of hubs. Lower-end hubs with poorer tolerances can lead to issues, namely damage to the bearings and races. Because we machine our own hubs with 5-axis CNC machines, we are able to manufacture hubs with higher concentricity. The 0.02mm tolerances our CNC machines are capable of, reduce the likelihood of uneven pressure on the bearings, extending their service life while reducing rolling resistance.

As a result of this precision machining, the feedback from tens of thousands of riders using ceramic bearing wheelsets since 2019 has been overwhelmingly positive. The wheels just keep on rolling.

10 comments

Diego

Salve, sono interessato ad acquistare ruote Marvel 38D. La mia domanda è questa: i mozzi che vengono montati su quelle ruote sono di tipo abbastanza silenzioso (tipo Shimano) o molto rumorosi? Mi riferisco al rumore che fanno quando si smette di pedalare. spero di essere stato chiaro. Grazie per la risposta.

Sergio

Hola, estoy pensando en comprar unas ruedas Drive 40D, recomendadas por vuestro embajador Martín Mata.

Me gustaría saber si el núcleo también lleva rodamientos ceramicos o solo son los bujes los que los llevan.

También me gustaría saber que tipo de grasa me recomendais a la hora de desmontar el núcleo y buje para su limpieza y mantenimiento.

Un saludo Sergio

Patrick

Hola sergio. Gracias por su pregunta. Todos los rodamientos son cerámicos. En cuanto a la grasa, recomendamos Shimano Premium Grease.

Nikolas

Patrick, I am interested of purchasing a good carbon wheelset with all the bells & whistles. After reading different articles on the cycling industry, they strongly mentioned that a wider carbon rim internal 23mm-25mm with a wider Tyre like 28mm-30mm will make the ride faster and smoother. The Elite 50D carbon wheels are 21mm internal width. Please explain. Thank you Nikolas

Patrick

Hello Nikolas. Thank you for your comment.

Our current road wheels can fit a 28mm or 30mm tire without any problems. They are aerodynamically optimized for 25-26mm tires, which coupled with our 28mm wide rims are more aerodynamic than wider ones. Wider rims and tires will not make you ride faster given appropriate tire pressures for the given tire size. To learn more about this, I recommend the independent testing site bicyclerollingresistance.com. They are free from biases that may be present in the cycling industry.

Wider tires can certainly offer more comfort in rough conditions. If you value comfort more than speed, I recommend you check out our Drive G45 gravel wheelset which can be fitted with road bike tires. The Drive G45 wheelset has a 24mm inner width and a 31mm outer width, making it perfect for 30mm tires.

Freddy

Saludos repecto a los wheels se le puden poner las graficas de ELITE SOLA y tambien si los colores del freehub y hub tambien cambian en colores anonizados?? Y si los bering son cerramic??

Elmer

What is the recommended brand of ceramic bearing that need replacement due to wear?

Patrick

Hi Elmer,

Thank you for your question. It really depends on which wheel you have as some have different size bearings. We use S&S bearings in many of our wheelsets. They are very smooth. Other brands offer excellent bearings as well.

If you would like more information about which bearings you need, you are welcome to contact our customer service. We also sell our recommended bearings on our website.

Mauricio cortes Robles

Hola precio para España (Granada)

Ruedas de 50 para disco

ya_manager

Hola Mauricio. Tenemos ruedas Marvel y Drive disponibles. El precio de las ruedas es el mismo en nuestra web.

Comments are closed.