Description

Specification

| Rim | |

| Series | Pro |

| Wheel Size | 27.5″ |

| Tire Compatibility | Tubeless |

| Rim Depth | 27mm |

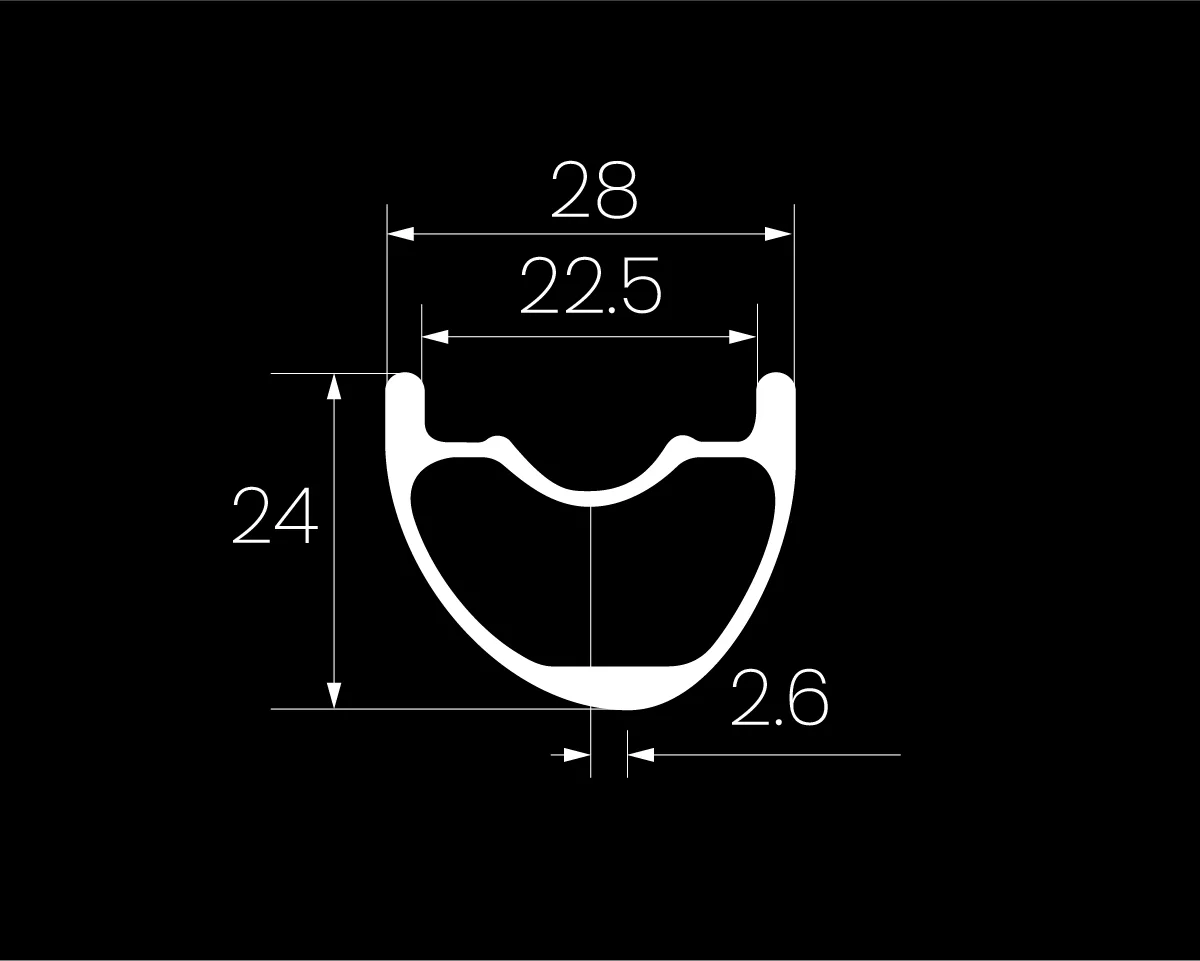

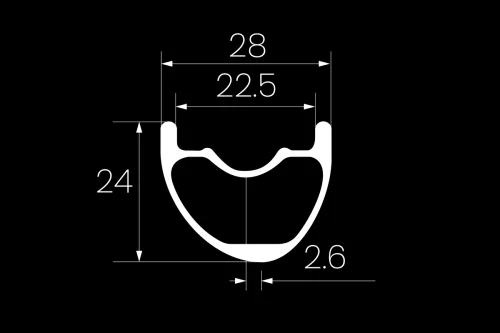

| Inner Width | 28mm |

| Outer Width | 35mm |

| Rim Profile | Asymmetrical |

| Offset | 3mm |

| Bead Type | Hookless |

| Other | |

| Assembly Method | Handbuilt |

| Rim Finish | Glossy Marbled |

| Max Tire Pressure | 50psi/3.4bar |

| Extras | Rim Tape(Installed), Tubeless Valves(Installed) |

| Weight (Pair) | 1650g+(See FAQ Data information) (without tubeless valves and rim tape) |

| Rider Weight Limit | 275lbs/125kg |

| Recommended Tire Sizes | 2.2″-2.7″ |

| Intended Use | Enduro / All-mountain |

| ERD | 547mm |

| Certification | CE Certified |

| Hub | |

| Front Hub Spacing | QR x 100mm / 15x100mm / 15x110mm |

| Rear Hub Spacing | QR x 135mm / 12x142mm / 12x148mm |

| Bearing | TPI Steel |

| Brake Compatibility | Disc (Center Lock/6-bolt) |

| Freehub Type | Ratchet System 36T |

| Freehub Compatibility | Shimano HG / SRAM XD / Shimano MS |

| Spoke | |

| Front Spoke Pattern | 3X/3X |

| Rear Spoke Pattern | 3X/3X |

| Spoke Count | 28F/28R |

| Spoke Type | Sapim CX-Ray |

| Nipple Type | Sapim Secure Lock |

all mountain wheels

RIMS

During the rim production process, internal inflatable bladders from a special material are used to produce smoother walls, resulting in a lighter rim. These bladders are then completely removed without the use of harsh chemicals through the valve hole. Our unique manufacturing process makes is so that the rim does not have to be patched to extract the bladders like traditional manufacturers. This significantly improves the strength of the rims.

RIM TYPE

We use both genuine Toray T700 and T800 carbon fiber which is superior to generic carbon fiber used by many manufacturers. The two types of carbon fiber are used in different places to increase the wheel’s strength to weight ratio while reducing lateral and radial forces as well as increasing impact resistance.

The rims have also been specifically designed to make sealing tubeless tires using a floor pump easy.

PERFORMANCE HUB

The Elitewheels PRO hub comes standard. DT Swiss hubs are also available.

The front and rear PRO hubs are made of 7075 aluminum alloy, the lightweight freebody features a ratchet system with 36 teeth.

The front and rear hubs use Taiwanese TPI bearings.

SPOKES

Sapim CX-Ray spokes come standard. We take precautions to ensure that spoke windup is minimized so wheels don’t go out of true. After the initial truing, the wheel is sideloaded. This process is repeated again. The wheels are sideloaded a total of 16 times. We see this as an essential quality control standard. As a result, our wheels are guaranteed to stay within 0.2mm of true.

In order to provide riders with the best wheelsets, we seek to update and improve them as technology advances. Elitewheels reserves the right to change, add or remove the information contained on this website at any time, including equipment, specifications, models, colors, materials, and pricing, without prior notice. The shipped products will be based on the actual order information. Elitewheels thanks you for your understanding and support.

Reviews

There are no reviews yet